Week 4: Avengers! ASSEMBLE!!

- Laura Wong

- Jan 31, 2022

- 6 min read

Updated: Feb 11, 2022

This week was our first week meeting up to work on the project at the same time in person! It was so fun because we could all work together effortlessly, and communication was waaay faster! In terms of progress, this week was huge for us, with putting our chassis together, finishing up our sensor testing, and further development. Yay us!!

Mechanical

Guess what? We started our mechanical build this week! AAAHH! EEEK! So exciting! We met up and stared to work on the build by putting together the wheels, testing out the magnets and putting different parts in their respective places (the switch, battery placement, etc.) After some hard work at the beginning of the week, we decided that to complete our build, we'd need to go onto campus to use some of their Allen keys and tools. And so our adventure on campus began... Before that, look at Shanika workin' hard on our pot:

|

After making our way on campus, we started to assemble our bot by screwing in our motors to their holders, attaching our mounting pieces, and we looked for battery connectors.

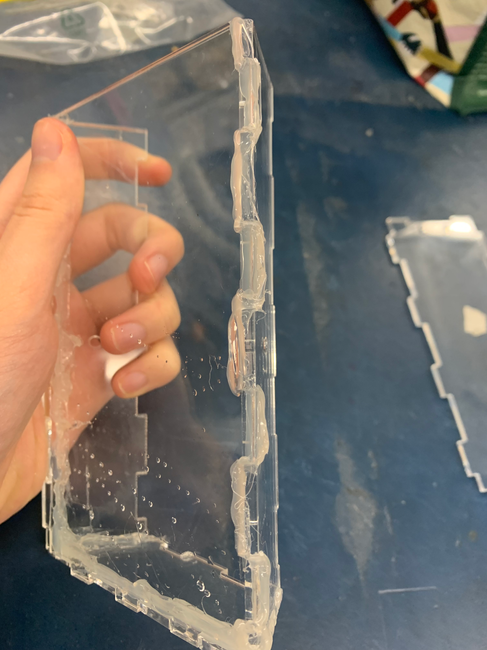

We also started to look into and do a small test with our water tank. Our initial plan was to glue it together using the gasket, but the gasket we found seemed too thin and didn't even have an adhesive side :(. Alas, we decided that we may have to glue the tank together, then apply the gasket on the outside and inside of the tank around the edges. This should help with the waterproofing! However, after doing some initial tests with just glue, we discovered that the tank was way too loose with water leaking at every possible crack. Due to this, Shanika decided that it would be better if we re-cut the tank with tighter tolerances, and this should significantly help with leaks. With this, we had to put a pause on tank testing until next week when we could cut new pieces for our tank.

The pictures below show the tank glued on the inside and the outside. Unfortunately, both led to leaks :(

Software and Electrical

Capacitive Touch Sensor

In terms of software and electrical, our copper tape finally arrived in the mail, meaning we could test out our capacitive touch sensor! As a reminder, this is our sensor for determining the water levels in our water tank. Before actually testing out the sensor, we first had to solder the pins onto our capacitive level sensing board. Thankfully, one of our friends had a spare soldering iron, which meant that we could easily solder all our components at home whenever we wanted. Look below for pics of Jess soldering our board and the final product!

|  |

Once we finished soldering the pins to the board, we were able to test the sensor. We plugged in our board to the breadboard for easier prototyping and connected it to our Arduino using I2C communication. Furthermore, with test code from Adafruit (the company who created the level sensing board), we were able to easily upload working code to our Arduino and test if the capacitive level sensor was being touched and when it was released. This simple test worked instantly with the Arduino with the status of the sensor being printed to the serial monitor. Due to this, we decided to test the sensor further by seeing the raw sensor data, this would be better for us in the long run as we could map the values to potential water level heights in our application. This was also done using Adafruit's test code and libraries, and running this also showed promising results with more accurate values being printed to the serial monitor. It did however take us a while to decode what all the print statements were doing in the test code, but after some trial and error we were able to see what part the sensor we were directly touching, and what its average value was. The picture below shows a breakdown of what each of the numbers represent in the output:

With the sensor working with simple human touch, we decided to test it further for our application: water level sensing. To do this we had to solder a wire to the level sensing board, and connect this wire to a cup of water with a conductive material on it. In our case, the copper tape. With our setup complete we started to test our sensor with an empty glass of water and filling it with more water slowly. We decided to use a glass cup as waterproofing for the acrylic tank was not complete yet, and the glass cup had a similar thickness as our acrylic (acrylic was 3mm, glass cup was around 3-4mm as well).

Unfortunately, through testing we got some pretty disappointing results 😥. Turns out, the sensor reading when our cup was empty was around 240 and when our cup was full it would read 200. This value difference of 40 was way too small to accurately determine how much water was left in our water tank, so more measures needed to be taken. After some research we discovered that increasing the surface area of our sensor would improve the capacitive touch sensor's sensitivity, and so, we decided to cover half the glass with the copper tape. BUT, doing this actually had no effect on the system, we were left puzzled and confused as to what we had to do. And so, we decided to read up more on capacitive level sensing to see if anything could help us determine how to make our sensor more sensitive. After some thought and more research, we realized that the way the sensor works is capacitance is sensed between our sensing plate and ground. However, we had no ground closeby... instead, we just had external sensing fields like our hands and the water. This meant that we needed to add ground strips between our sensing strips... or just ground in general! After taking a lot of the copper tape off our initial setup, and connecting an additional wire to the copper tape we tested out the sensor once again and the results were EMACULATE! IT WORKED SO WELL! Peep below for our test set-up.

|  |

After adding in a separate strip just for ground, our sensor values ranged from 240 to 90!! It was amazing, when we increased the level of water in our cup by 5cm, the sensor value would decrement by 20 points. This accuracy would be sufficient in accurately determining the level of water left in our system, meaning the level sensor testing was complete! Watch our video below of our capacitive level sensor working live!

With our capacitive touch sensor working as expected we only had one more component to validate and this was the motors. Unfortunately, we weren't feeling too confident using our batteries right away to test out the motors, so we decided that we could go on campus and make use of the power supplies there!

Motor Validation

After a trek through the snow we finally made it to campus and were able to test out our wheel motors and pump! We were a little hesitant to test them out just because they were powered by 12V which is a lot and scary, but with some help from Andy we were on the right track. Additionally, to see how the motors would work with their respective loads and to help visualize the speed we attached the motors to the wheels and tested out the pump in water. See below for a video of our wheels spinnin' and the pump pumping water! A few notes on some issues we encountered while testing out the motors though. We encountered an issue with the power supply where it would constantly make a beeping noise after attaching our motor, turns out we were already exceeding our current limit (which we had set to a small value because we were afraid of accidentally burning out the motors). However, Andy helped us with this issue and told us that we should actually be setting the current limit to the max current the motor runs at as specified on the data sheet. This meant that for our wheel motors we should be setting the limit to 3mA, and 2mA for our pump motor!

Other

In terms of other things we completed this week, we finally decided on our team name and logo! We decided to go with Plant Buddy as our autonomous bot is a cute little friend who can tend to your plants. We also got help from some friends to design a logo for our company which we'll be using on our matching t-shirts (stay tuned for more on this :)) ).

This week we also finished up our product description and taking headshots! It took us a while, but we managed to describe our entire product in a measly 85 words for the capstone brochure information! We also managed to spend almost like an hour taking headshots for our brochure (hehe oops) but we finally got some good ones! You can see them on our about page, and might I say, we're lookin' pretty darn cute in them too 😻

Comments